If your real estate offering is bulging, it's time to upgrade to a capacity folder. Each day at DATAGRAPHIC, we get a chance to create … [Continue]

5-Star Printing Services in NYC by DATAGRAPHIC

LARGE FORMAT PRINTING FOR BIG IMPACT

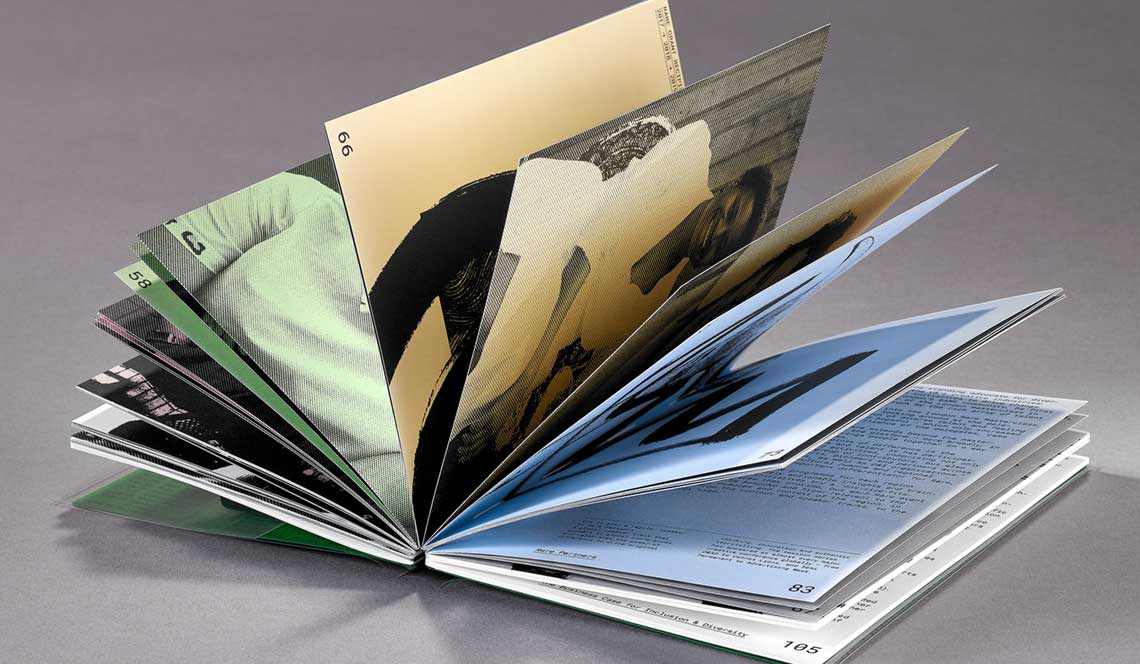

LARGE FORMAT PRINTING FOR BIG IMPACT EXPOSED SMYTH SEWN BOOK FOR RARE WITH GOOGLE

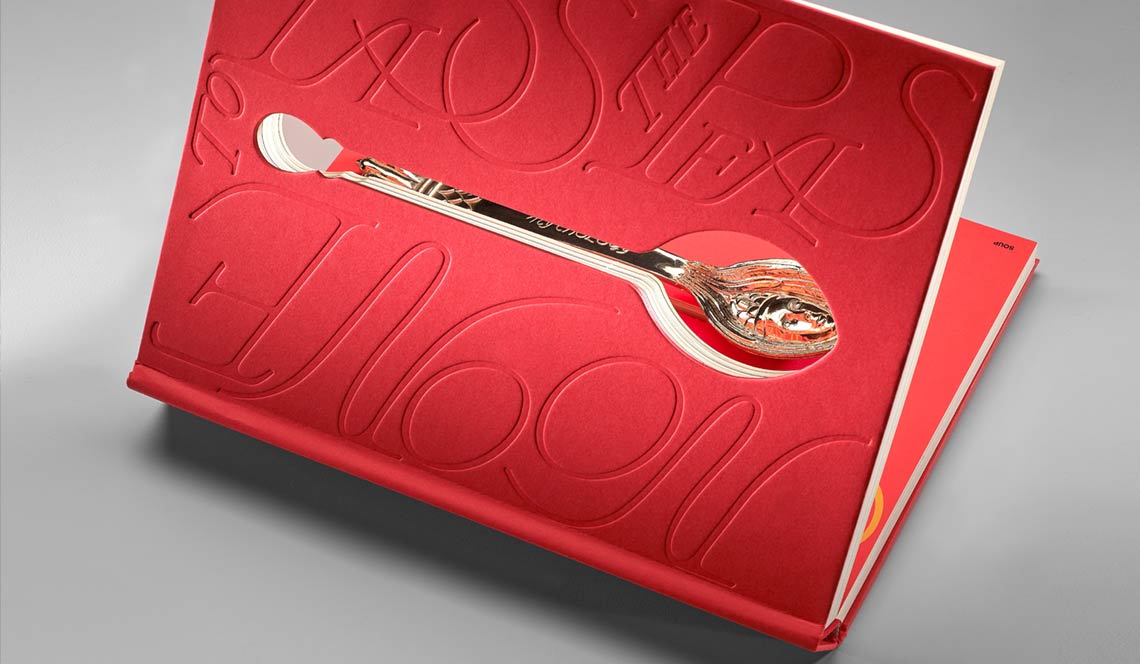

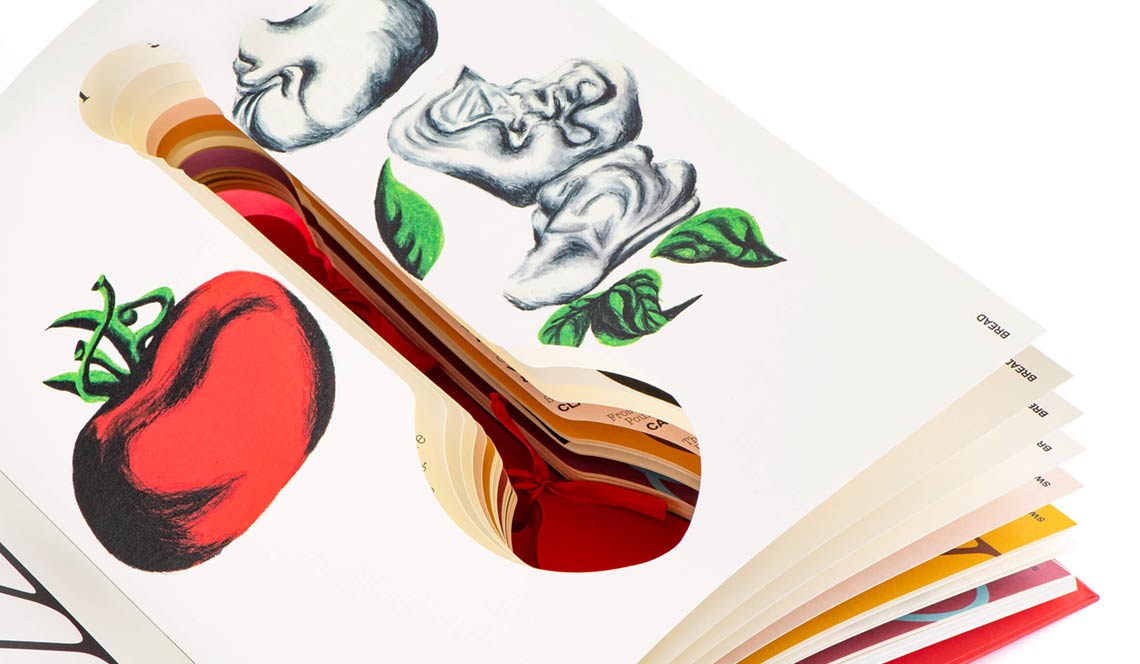

EXPOSED SMYTH SEWN BOOK FOR RARE WITH GOOGLE DIE CUT BOOK FOR MYTHOLOGY

DIE CUT BOOK FOR MYTHOLOGY CUSTOM PARTY INVITE FOR NFL

CUSTOM PARTY INVITE FOR NFL LUXURY BRANDED STATIONERY FOR MARCHIONESS

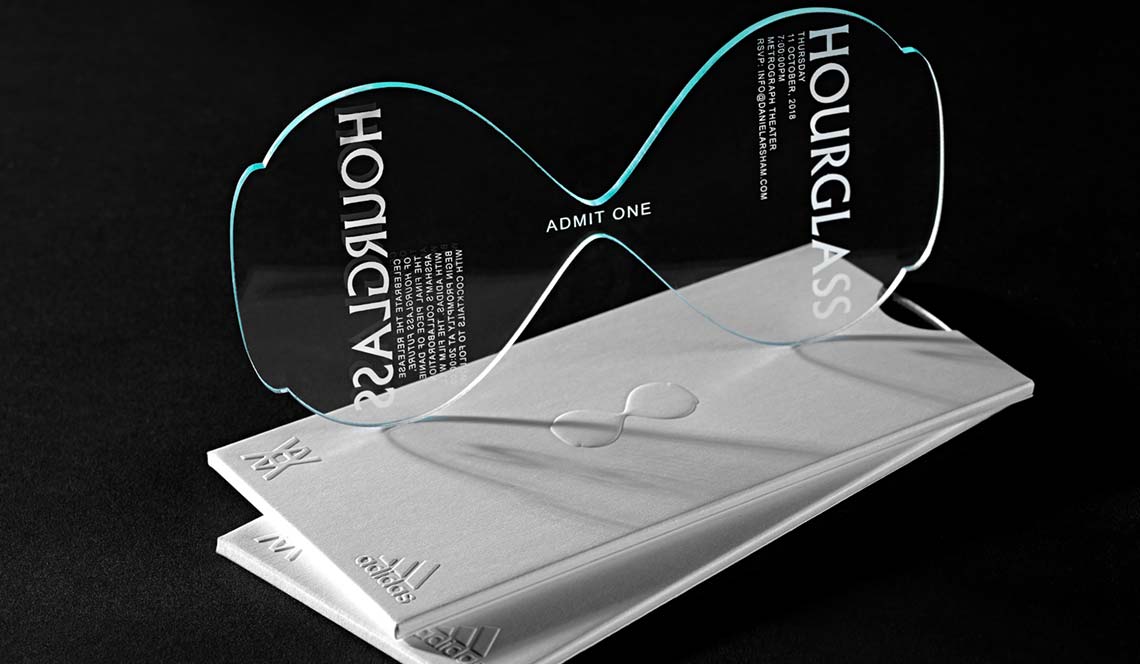

LUXURY BRANDED STATIONERY FOR MARCHIONESS LASER CUT PLEXIGLASS INVITATION FOR ADIDAS

LASER CUT PLEXIGLASS INVITATION FOR ADIDAS LUXURY ALCOHOL PACKAGING FOR AGUA MÁGICA MEZCAL

LUXURY ALCOHOL PACKAGING FOR AGUA MÁGICA MEZCAL HONEY PACKAGING FOR STAG&HARE

HONEY PACKAGING FOR STAG&HARE

PUZZLE AND GIFT BOX FOR BLOOMINGDALE’S

PUZZLE AND GIFT BOX FOR BLOOMINGDALE’S DIE CUT BOOK FOR MYTHOLOGY

DIE CUT BOOK FOR MYTHOLOGY "SLOW MOVING LUMINARIES" EXHIBITION CATALOG

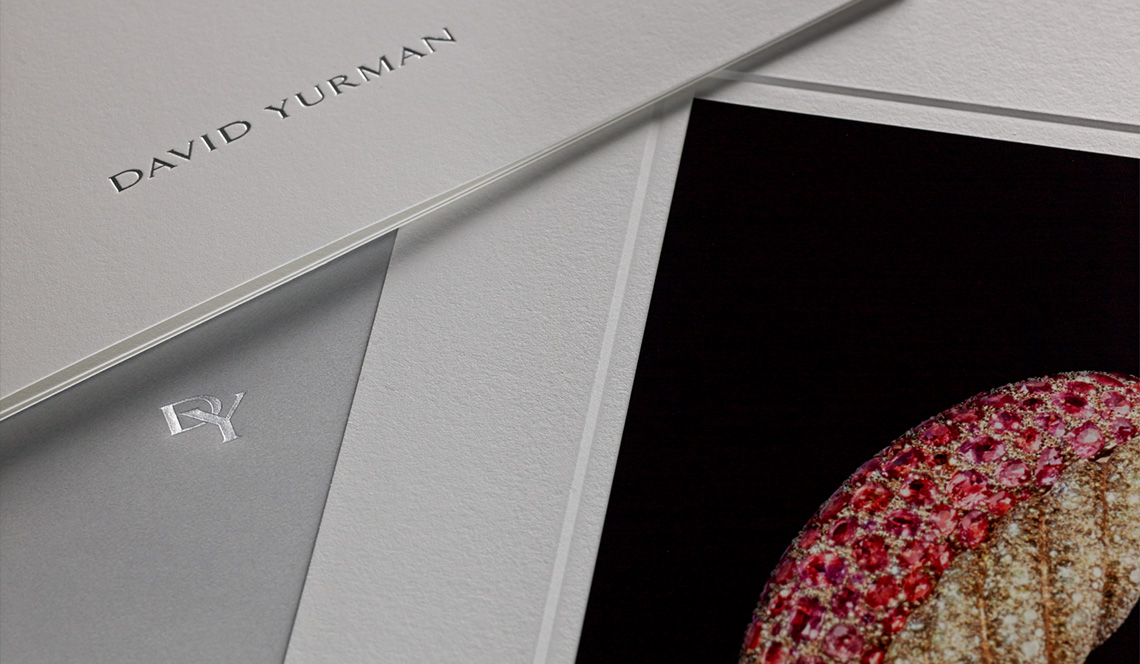

"SLOW MOVING LUMINARIES" EXHIBITION CATALOG DAVID YURMAN HIGH JEWELRY BOX

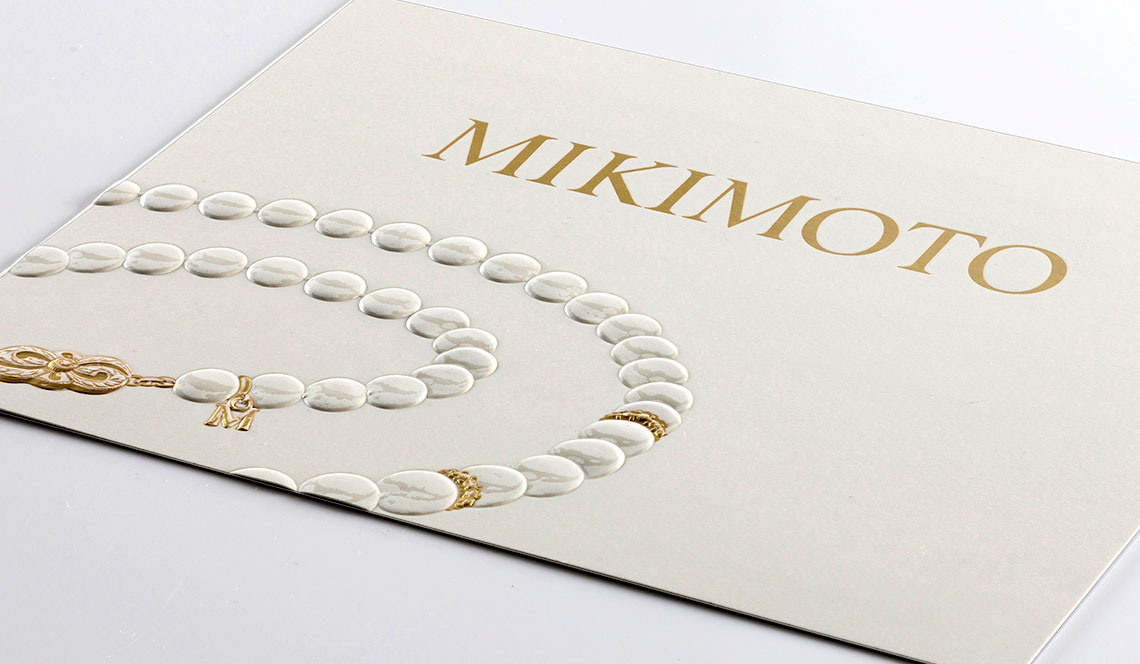

DAVID YURMAN HIGH JEWELRY BOX MIKIMOTO FOIL STAMPED MAILER

MIKIMOTO FOIL STAMPED MAILER

We are a 97 year-old family business delivering best-in-class printing services in NYC including: offset lithography, digital printing, engraving, letterpress, screen printing, book printing & binding, large format printing and more!

TRUSTED BY THESE BRANDS and MORE!

Hot Off the Press

Below are just some of the incredible printing and packaging projects we’ve had the opportunity to produce. Whether you’re searching for a commercial printer in NYC, digital printing or graphic design printing services, see how we bring our customers’ visions to life.

Beautiful Sculpted Emboss Notecard Set

This award-winning sculpted emboss notecard set will have you wondering "how did they do that?!" At DATAGRAPHIC, we love creating print … [Continue]

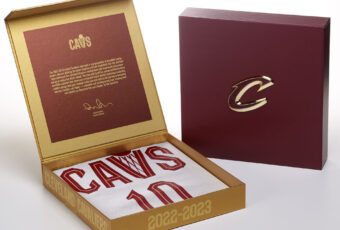

Seeding Kit Packaging for Cleveland Cavaliers

A successful seeding kit needs to excite and inspire and that's exactly what the Cavs did with their 2022-2023 jersey kit. Featuring an … [Continue]

Embossed Invitation Folio for Flexjet

A blind embossed invitation folio for an event too exclusive to mention. Psst! At DATAGRAPHIC, we occasionally get to work on print … [Continue]

Exceptional Resort Marketing Materials for Nemacolin

Bespoke resort marketing materials for a truly bespoke resort experience. Designed as an exclusive, no-limits membership to the luxury … [Continue]

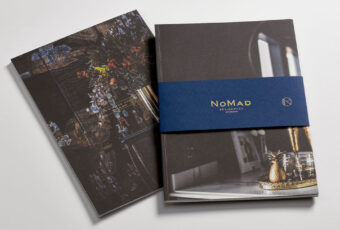

Distinctive Real Estate Collateral for NoMad Residences

With a glint of artful foil we elevated this real estate collateral suite to museum-quality heights. NoMad Hotels are world renowned for … [Continue]

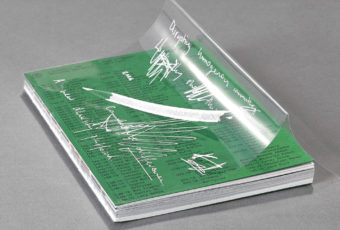

Exposed Smyth Sewn Book for Rare with Google

White ink on a clear jacket finishes off this exposed Smyth sewn book like nothing else could. The Rare with Google initiative began with … [Continue]

Hardcover Brand Book for Marla Aaron

The deep impressions on this hardcover brand book set the stage for style. We were asked to produce a gorgeous hardcover brand book for … [Continue]

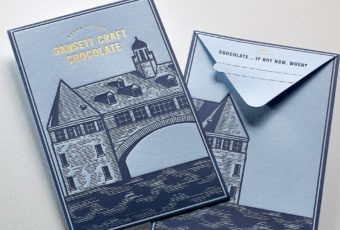

Letterpress Packaging for Gansett Craft Chocolate

Letterpress packaging for a chocolate bar that you just know will taste special. "Beans-to-bar" chocolatiers, Gansett Craft Chocolates, … [Continue]

Delicious Influencer Box for U.S. Women’s Open

The deceptively delectable golf balls in this influencer box are surely destined for a hole-in-one. Getting folks excited about a big … [Continue]

Luxury Skincare Packaging for Into

Uncommon ingredients meet bio-inspired designs in this striking skincare packaging suite. Breaking new ground in an established … [Continue]

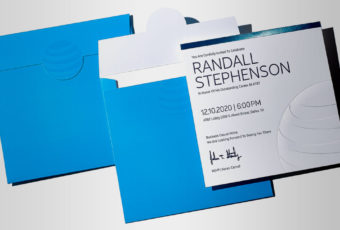

Custom Envelopes and Envelope Printing

When your idea deserves more than just a paper sleeve, we offer custom envelopes. Available in any size, color and paper stock, custom … [Continue]

Looking for a Commercial Printer in NYC?

Our presses are running and are waiting for your job!

Over 100 5-Star Google Reviews and Growing!

Customers love our NYC printing services! Below are just a few of our more than 100 5-Star Google reviews:

STILL HAVE QUESTIONS?

Printing is our passion! Let us help you find the right process or finish.

EVERY DOOR DIRECT MAIL

We’re pleased to offer Every Door Direct Mail® (EDDM®) services to promote your small business in your local community. If you’re having a sale, opening a new location, or offering coupons, EDDM can help you send postcards, menus, and flyers to the right customers. Please contact us to learn more about this exciting new service.

NYC Printing Services

Check out the many in-house printing services and finishing techniques we offer below. We are multi-process masters who love combining different techniques to create new effects. Please contact us if you you are looking for a particular finishing that’s not showcased here.

WE ARE PROUDLY G7 MASTER QUALIFIED AND FSC® CERTIFIED